Exploring After Sales Service Benefits and Repair Costs in Best Glass Manufacturing Process for Future Innovations

In today's competitive market, understanding the intricacies of the Glass Manufacturing Process is essential for companies aiming to enhance their after-sales service and reduce repair costs. This blog will delve into the various benefits that effective after-sales service can provide to manufacturers and consumers alike, emphasizing its critical role in fostering customer loyalty and ensuring product longevity.

We'll explore the innovative practices currently reshaping the glass industry, highlighting how advancements in manufacture and service can lead to improved operational efficiency and sustainability. By examining case studies and expert insights, readers will gain a comprehensive view of how optimizing after-sales service can not only mitigate costs associated with repairs but also position businesses favorably in a rapidly evolving market landscape. Prepare to uncover actionable strategies and implement forward-thinking solutions that align with the best practices in glass manufacturing.

Exploring the Key Technical Parameters of High-Quality Glass Products

In the realm of high-quality glass production, understanding the key technical parameters is crucial for innovation and competitiveness. As glass substrates become increasingly central in advanced industries such as artificial intelligence (AI) and high-performance computing (HPC), manufacturers must focus on the material's physical properties, such as strength, clarity, and thermal stability. These attributes not only enhance performance but also cater to the evolving demands of electronic devices that require superior substrate solutions for better integration and durability.

The recent surge in sales within the optical sector underscores the significant role of high-quality glass products in driving economic growth. For instance, a leading optical company recently achieved impressive daily sales figures, indicating a robust market for high-grade glass. This momentum suggests that manufacturers should prioritize innovative processes and after-sales services to maintain quality standards while addressing repair costs, thus ensuring customer satisfaction and brand loyalty. By investing in these key areas, glass manufacturers can foster a modernized industrial system that embraces both technological advancements and market demands.

Exploring After Sales Service Benefits and Repair Costs in Glass Manufacturing

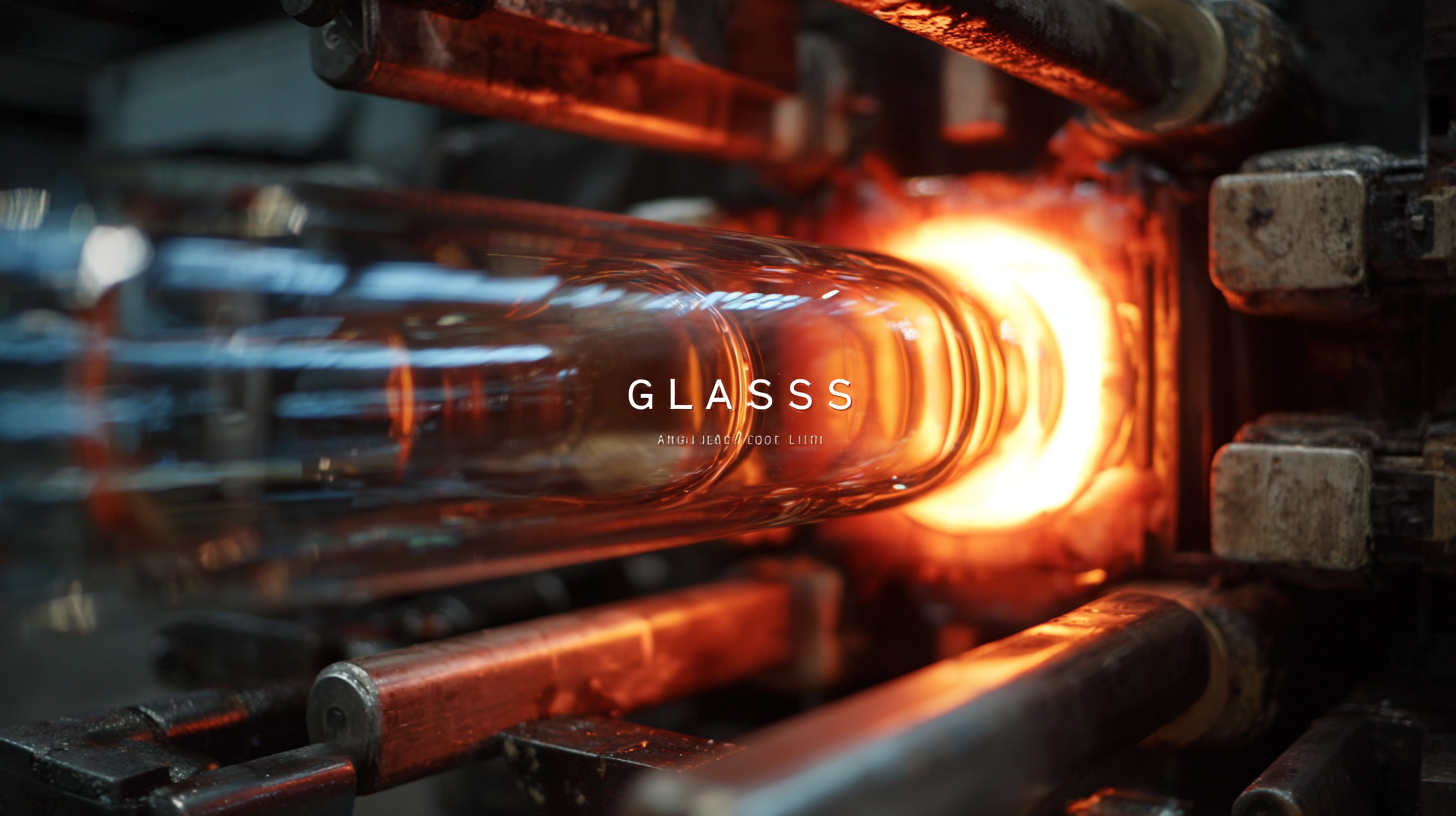

This chart illustrates the relationship between after-sales service benefits and repair costs in glass manufacturing, highlighting key technical parameters for high-quality glass products.

Understanding the Financial Impact of After Sales Services in Glass Manufacturing

In the competitive landscape of glass manufacturing, after-sales services play a pivotal role in enhancing customer satisfaction and driving financial performance. A robust after-sales service strategy not only addresses customer concerns promptly but also contributes to brand loyalty and repeat purchases. By providing reliable support and maintenance, manufacturers can reduce the occurrence of faults, ensuring customers receive maximum value from their products while minimizing repair costs. This can significantly decrease the overall lifetime costs for customers, thereby enhancing the perceived value of the manufacturer’s offerings.

Moreover, the financial implications of these services extend beyond immediate customer engagement. By investing in after-sales support, glass manufacturers can gather valuable data on product performance and customer preferences, which can inform future innovations. This continuous feedback loop helps companies refine their manufacturing processes and product designs, ultimately leading to enhanced efficiency and reduced waste. Thus, prioritizing after-sales services not only positions manufacturers as leaders in customer service but also aligns their operational strategies with long-term financial success.

Analyzing Repair Costs and Their Influence on Customer Satisfaction

The rising repair costs in the automobile sector have become a significant concern for consumers, particularly in the electric vehicle market. A recent report highlighted that the replacement cost of battery systems in new energy vehicles can soar to 120,000, almost half the original price of the vehicle. Such exorbitant expenses can dramatically impact customer satisfaction and loyalty. With the U.S. automotive repair and maintenance market projected to exceed $183.5 billion by 2023 and grow annually by approximately 10.1% through 2032, the importance of optimizing after-sales service is more pivotal than ever.

Tips: To enhance customer satisfaction amidst rising costs, manufacturers should focus on transparent pricing strategies that inform customers about potential repair expenses upfront. Additionally, investing in after-sales service training can improve service delivery quality, fostering trust and loyalty among consumers.

The connection between repair costs and customer satisfaction cannot be overstated. As vehicle ownership increases, understanding customer pain points regarding after-sales service will become essential for manufacturers. By analyzing repair costs and integrating customer feedback, companies can devise solutions that not only lower repair expenses but also enhance the overall ownership experience, ultimately driving innovation in service strategies.

Innovative Technologies Shaping the Future of Glass Manufacturing Processes

The landscape of glass manufacturing is undergoing a transformative shift thanks to innovative technologies that are redefining processes and enhancing efficiency. As artificial intelligence continues to weave its way into manufacturing, organizations are leveraging AI-enhanced monitoring systems to streamline production, reduce waste, and ensure the reliability of their products. This integration of advanced technology allows manufacturers to respond proactively to issues, ultimately leading to enhanced after-sales service and reduced repair costs.

Moreover, recent advancements in material science are paving the way for new types of glass. Innovations such as engineered transparent wood present exciting possibilities for sustainable glass applications. These developments signal not only a shift in the materials used but also an opportunity to improve energy efficiency across the production cycle. As companies invest in these cutting-edge technologies, the focus on decarbonization and sustainability gains traction, positioning the glass industry for a promising future that prioritizes innovation and environmental responsibility.

Exploring After Sales Service Benefits and Repair Costs in Best Glass Manufacturing Process for Future Innovations

| Service Parameter | Benefit | Average Repair Cost ($) | Impact on Customer Satisfaction |

|---|---|---|---|

| Warranty Coverage | Increases trust in products | 150 | High |

| Technical Support | Reduces downtime | 100 | Medium |

| Installation Services | Ensures proper functionality | 200 | High |

| Repair Services | Prolongs lifespan of products | 80 | Medium |

| Training Programs | Enhances user experience | 50 | High |

Assessing Top Types of Glass Products for Enhanced Durability and Performance

The glass manufacturing industry is evolving with a focus on enhancing durability and performance across various product types. One of the most significant advancements in this realm is the development of tempered glass. This type of glass undergoes a rigorous heating and cooling process, resulting in increased strength and impact resistance. Ideal for applications in both residential and commercial spaces, tempered glass not only offers safety benefits but also aesthetic appeal, making it a popular choice for modern architecture.

Another noteworthy innovation is the integration of laminated glass, which features multiple layers bonded together to provide superior sound insulation and UV protection. This type of glass is especially beneficial for high-traffic areas where noise reduction is essential, and it effectively blocks harmful ultraviolet rays, protecting both interior furnishings and the health of occupants. As consumers increasingly prioritize energy efficiency and sustainability, the demand for glass products that deliver exceptional performance without compromising environmental integrity continues to rise, driving further innovations in the glass manufacturing process.